Services - finite element analysis

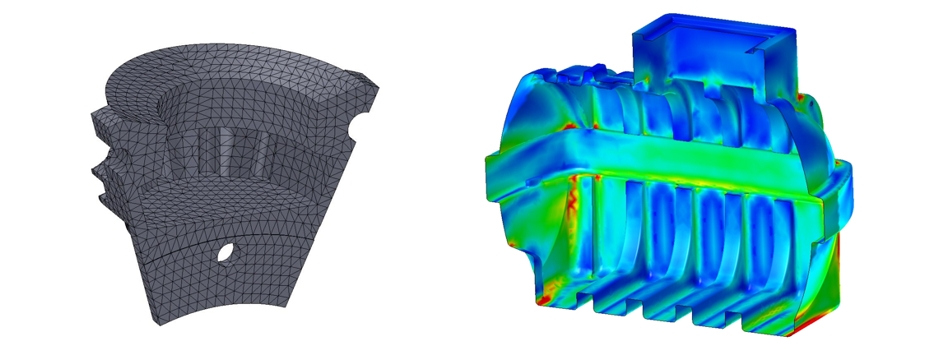

Finite element analysis (FEA) is a powerful

tool for understanding the limitations of

mechanical designs. In the right hands it can

quickly identify problems, show where designs

can be improved, save weight and reduce cost.

It can provide the information for fatigue,

creep and lifing predictions. We have been

providing FEA solutions to our clients since

1997.

FEA is quicker and more accurate than hand

calculations in all but the simplest cases. It

handles complicated assemblies and loads,

large deflections and contacting parts. It

must be used with care though, because

assumptions often have to be made about the

loads and supports (boundary conditions) and

how to simplify complicated geometry. We often

use hand calculations to check that our FEA

results are reasonable and expected.

Experienced FEA practitioners also use various

standard checks to make sure the model is

performing correctly.

FEA is often used in combination with

appropriate design standards. We use various

BS EN, ISO, ASME and other standards – see the

case files for more details.

We use FEA extensively as a tool to find the

best strategy for tackling a new design

problem, including evaluating different

materials and design approaches. Once an

outline design has been agreed, we use FEA to

optimise it. This saves the cost and time of

making several prototypes. Many of our clients

have saved considerable amounts or gained a

market advantage in this way.

Our FEA work includes:

- Linear static stress analysis

- Varying pressure and thermal loads

- Geometric non-linearities (large

deflection, large strain, friction and

contacts)

- Optimising for weight, cost or other

constraints

- Balancing loads to give minimum deflection

- Improving rigidity

- Finding the causes of cracks and other

failures

- Fatigue and creep lifing predictions

- Metal, plastic, rubber, composite and

timber components and assemblies